Acoustical Breakdown of Materials by Focusing of Laser-Generated Rayleigh Surface Waves

Fig. 1. Images on the cover of July 17 2017 issue of Applied Physics Letters show focusing surface acoustic waves and the resulting damage of a gold coating on silica substrate

- Surface acoustic waves (SAWs), also known as Rayleigh waves, play an important role in many areas of science and technology from seismology to signal processing and non–destructive material characterization.

- In a recently published paper, we report the visualization of focusing of laser-generated high-amplitude surface acoustic waves leading to material damage.

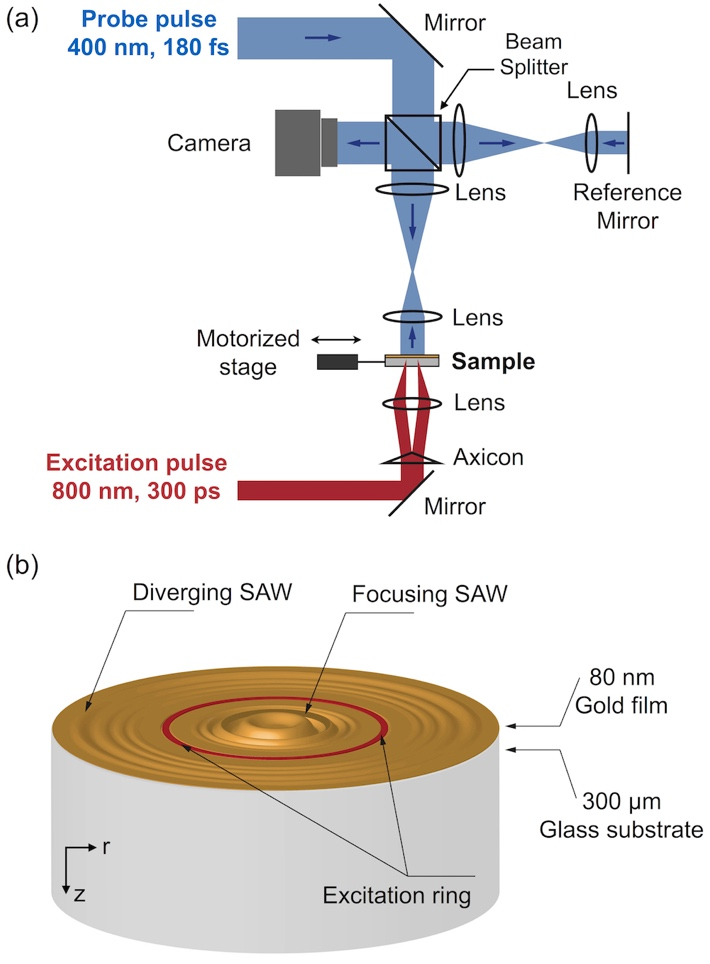

- The optical excitation is shaped using a lens and an axicon that focuses an intense picosecond excitation pulse into a ring pattern at the surface of a gold-coated glass substrate. Following optical excitation, a surface acoustic wave (SAW) propagates in the plane of the sample and converges toward the center.

FIG. 2. Optical setup and sample configuration. (a) The axicon-lens combination is used to focus the excitation into a ring on the gold-coated surface of the glass substrate. The surface is imaged onto a CCD camera at 10× magnification using a variably delayed femtosecond probe pulse and a Michelson interferometer configuration to obtain interferometric images of the surface displacement. (b) Sample configuration schematically showing the ring-shaped excitation and propagation of focusing and diverging SAWs.

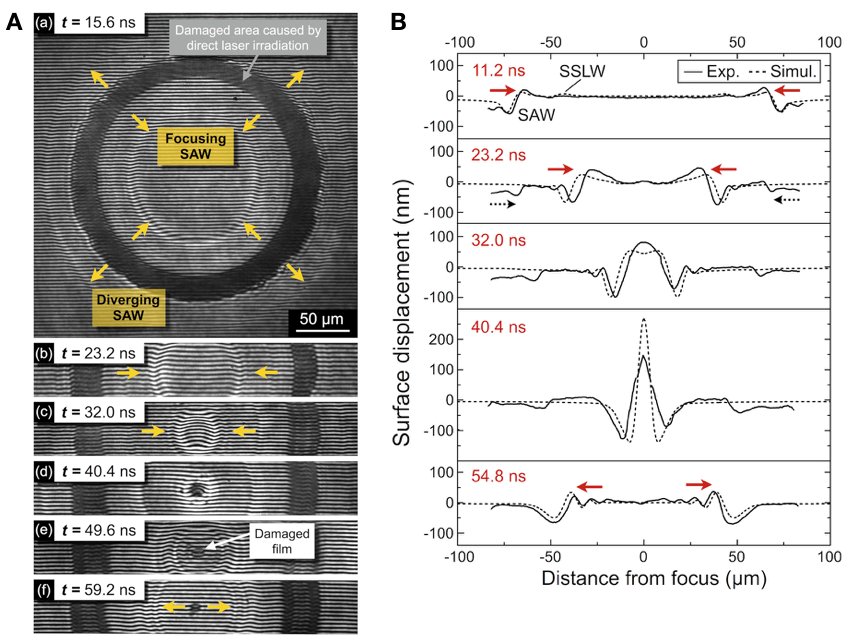

- The evolution of the SAW profile is monitored using interferometry with a femtosecond probe pulse at variable time delays. The quantitative analysis of the full-field images provides direct information about the surface displacement profiles, which are compared to calculations.

FIG. 3. A. Interferometric images of propagating SAWs recorded with varying delay between the excitation pulse and the imaging probe pulse at a laser excitation fluence of 2.5 J/cm2. (a) CCD image at a delay of 15.6 ns. The propagating SAW is characterized by a bend in the interference fringes. The directions of the SAW propagation, inward and outward, are indicated by yellow arrows. The dark ring is formed due to the removal of the gold coating along the laser irradiation ring. (b-f) Cropped CCD images at increasing delays show focusing (b-d) of the SAW followed by divergence (e,f). After the convergence of the SAW, a black spot appears at the focal point revealing damage in the gold film caused by the SAW (e,f). B. Measured (solid curves) and calculated (dashed curves) vertical surface displacement profiles at different delays at 2.5 J/cm2 excitation fluence. The SAW propagation direction is indicated by red solid arrows. The weaker surface skimming longitudinal wave (SSLW) is also detected. Positive values correspond to outward displacements. The blast wave contribution to the phase shift is indicated by dotted black arrows.

- The high stress at the focal point leads to the removal of the gold coating and, at higher excitation energies, to damage of the glass substrate.

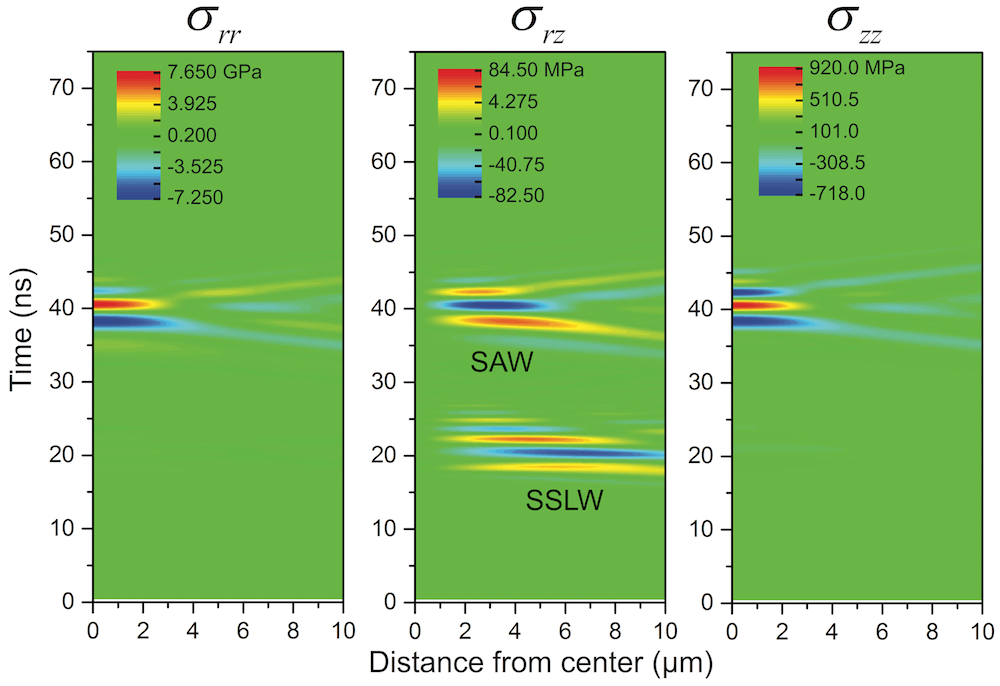

- The computer maximum positive (tensile) szzvalue of 2.4 GPa is reached inside the glass substrate at a depth of 3.5 µm and we note that both srr and szz greatly exceed the static tensile strength of both gold and borosilicate glass (30 to ~400 MPa for gold depending on film thickness and 20-200 MPa for glass).

Fig. 5. Stresses computed close to the focus at the film-substrate interface. The scale bars show the maximum and minimum values reached for each stress component.

- This approach opens a prospect for testing material strength and adhesion of coatings at ultrahigh strain rates. SAWs offer some possibilities not accessible in the more conventional shock spallation approach, such as studying crack initiation at the free surface.

- Read the paper: D. Veysset, A. A. Maznev, I. A. Veres, T. Pezeril, S. E. Kooi, A. M. Lomonosov, and K. A. Nelson, Appl. Phys. Lett. 111, 31901 (2017).